In the highly competitive and complex landscape of the downstream oil industry, maintaining operational efficiency and minimizing unplanned downtime are critical to profitability. Predictive maintenance, powered by artificial intelligence (AI), has emerged as a transformative approach that enables refineries to foresee equipment failures before they occur, thereby reducing downtime and maintenance costs. This blog post explores how AI algorithms are revolutionizing predictive maintenance in refineries.

Follow us for the latest AI thought-leadership

The Challenge of Traditional Maintenance Methods

Traditional maintenance strategies in refineries typically involve either reactive maintenance, where equipment is repaired after a failure, or preventive maintenance, which schedules repairs at regular intervals regardless of equipment condition. Both approaches have significant drawbacks. Reactive maintenance can lead to unexpected downtime and costly emergency repairs, while preventive maintenance can result in unnecessary parts replacement and labor costs due to maintenance being performed too early or too frequently.

How AI Transforms Predictive Maintenance

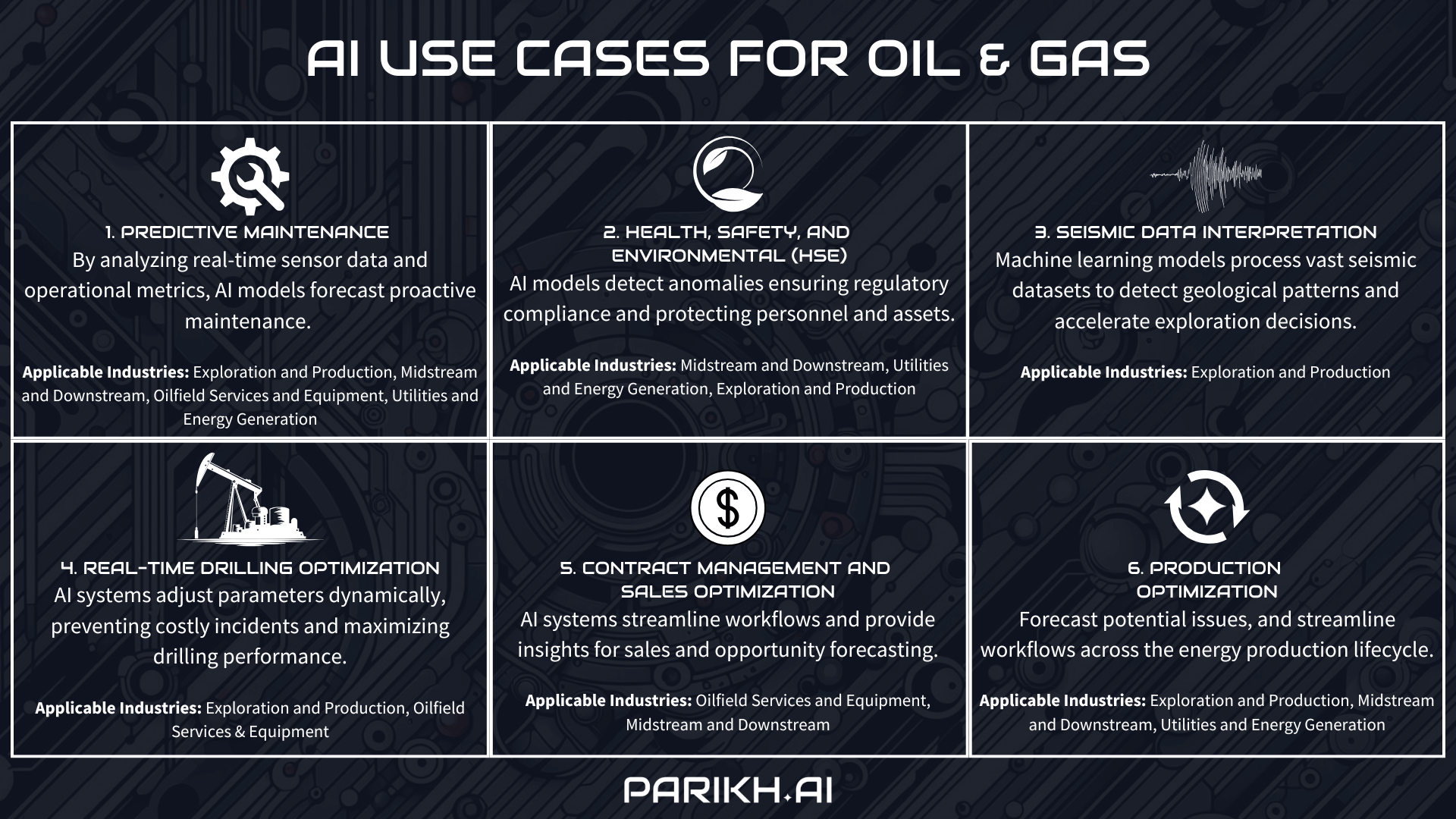

AI-driven predictive maintenance leverages advanced algorithms and machine learning to analyze historical and real-time data from various sensors and systems within the refinery. These AI models are trained to recognize patterns and anomalies that indicate potential equipment failures, allowing maintenance teams to take proactive measures before a failure occurs.

Data Collection and Analysis:

-

- IoT Sensors: Internet of Things (IoT) sensors collect real-time data on equipment conditions, such as temperature, pressure, vibration, and more. This data is continuously monitored and fed into AI systems for analysis.

- Historical Data: AI algorithms analyze historical data to understand normal operating conditions and identify deviations that may signal a potential failure (IET EngX).

Predictive Algorithms:

-

- Machine Learning: Machine learning models analyze the collected data to predict when equipment is likely to fail. These models improve over time as they learn from new data inputs, becoming increasingly accurate in their predictions.

- Anomaly Detection: AI systems can detect anomalies in equipment behavior that human operators might miss. By identifying these early warning signs, AI can alert maintenance teams to potential issues before they lead to significant problems.

Proactive Maintenance Planning:

-

- Condition-Based Maintenance: AI enables condition-based maintenance, where repairs are performed based on the actual condition of equipment rather than a fixed schedule. This approach ensures that maintenance is only carried out when necessary, optimizing resource utilization and reducing unnecessary costs.

- Optimized Resource Allocation: Predictive maintenance allows for better planning and allocation of maintenance resources. By knowing in advance which equipment needs attention, refineries can schedule maintenance during planned downtime, minimizing disruptions to operations.

Benefits of AI-Driven Predictive Maintenance

-

- Reduced Downtime: By predicting equipment failures before they occur, AI helps refineries avoid unexpected shutdowns, increasing operational uptime and productivity.

- Cost Savings: Predictive maintenance reduces the need for emergency repairs and optimizes the use of maintenance resources. This results in significant cost savings on labor, parts, and downtime-related losses (IET EngX).

- Extended Equipment Lifespan: Regular, condition-based maintenance helps maintain equipment in optimal working condition, extending its lifespan and improving overall asset performance

- Enhanced Safety: By preventing unexpected equipment failures, predictive maintenance enhances safety for refinery workers. It reduces the likelihood of accidents and hazardous incidents (Oilman Magazine).

Real-World Applications and Success Stories

Refineries have already successfully implemented AI-driven predictive maintenance solutions. For example, a leading oil and gas company leveraged AI to monitor the condition of its critical equipment, resulting in a significant reduction in unplanned maintenance events and increased operational efficiency (Deloitte).

AI-driven predictive maintenance represents a significant advancement in refinery operations, providing a proactive approach to equipment management that reduces downtime and maintenance costs. As the technology continues to evolve, more refineries are expected to adopt AI solutions to enhance their operational efficiency and competitiveness. By leveraging the power of AI, the downstream oil industry can achieve greater reliability, safety, and profitability in its operations.

Connect with the Parikh AI team to learn how your organization can stay ahead of the competition.